Author: Roger Gimbel, Gimbel & Associates

Nothing really beats the feel and smell of a freshly printed piece. Designing brochures, books, cards, or packages that are eventually produced in tangible form feeds our senses and is immensely satisfying.

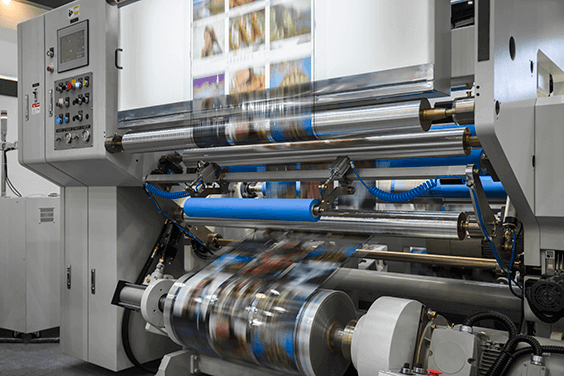

The process of printing those creations is also intricate and complex. Printing is a finely tuned and calibrated engineering feat with thousands of parts all moving in perfect harmony. On top of that, various technologies execute the function in different ways. While the nitty gritty engineering behind those technologies is best left to hardcore printing nerds, it helps to know which press is most appropriate for your projects.

Here, then, is a printing press primer.

Offset Presses:

Offset, or offset lithography, refers to traditional printing presses used to produce brochures, magazines, business cards, posters, books, flyers, and more. The term refers to how ink is applied to the paper. A printing plate is made for each color to be printed. After the plate is inked, it transfers, or offsets, the image to an imaging roller, which then images the paper.

Offset uses the long-established CMYK color system— cyan, magenta, yellow and black — along with premixed Pantone colors that ensure consistency. Many modern offset presses can handle up to 12 colors, and most execute finishes such as varnishing and coating.

These presses print on a variety of coated and uncoated paper stock with a smooth surface.

If you’re looking to print long runs of static pages with top quality and brilliant colors, then offset is your best bet.

Digital Presses:

Digital printing refers to any press that prints directly from a computer, without having to make plates. Two press technologies fall in this category.

- Electrophotographic or toner presses: Toner presses made their debut in the early 90s and have achieved a prominent place in the printing world. They differ from offset presses in two significant ways: they use toner instead of ink and they can produce variable jobs, in which each sheet in a run can be different. Early models produced what was called pleasing color, but modern versions produce high-quality hues that are almost indistinguishable from offset quality. They can also use Pantone colors and can create embellishments. Short runs are much more economical on a toner press than an offset press. Variable work, such as personalized direct mail or promo pieces, is only possible with this technology.

- Inkjet presses: Offset presses and toner presses print by having the substrate come in direct contact with an imaging cylinder. Inkjet presses use a contactless form of printing. Clusters of inkjet heads spray ink droplets onto a substrate. Because of this, inkjet presses are very versatile and can accommodate a huge variety of rigid and soft substrates in thicknesses up to about two inches. Inkjet can print on just about anything. Inkjet presses are available in sheetfed and web models, much like toner presses, and produce the same products, including variable work.Other inkjet presses are often called large-format devices which come in roll-to-roll and flatbed configurations. Some roll models can reach up to 12 ft. in width and are used to produce vehicle wraps, murals, billboards, and other large images. Flatbeds feature a flat bed where rigid substrates, like foamboard, glass, doors, or even tiles, can be printed. Both produce vivid colors and both can produce variable work.

Screen Presses:

Screen technology uses woven pieces of fabric — screens — to transfer an image onto a substrate. Some areas are coated with a non-permeable solution, and the press covers the remaining spaces in ink. The screen is then pressed against the substrate to print. The press needs one screen for each color. The advantage of screen printing is that the surface of the substrate doesn’t have to be flat and smooth. The ink can adhere to a wide range of materials, such as paper, textiles, glass, ceramics, wood, plastics, and metal.

Printers traditionally use screen presses for long runs of posters, signage, labels, wallpaper and textiles, specialty applications, and anything else you can imagine.

Screen printing is slowly being replaced by inkjet technology which has the same breadth of acceptable substrates but is cheaper to operate.

Flexographic Presses:

Flexographic presses are web-fed devices — web is printer speak for roll — that use rubber photopolymer plates with raised images. Ink is applied to the plates and transferred to the substrate. It can be very effective and flexographic presses feature the simplest imaging structure.

Labels and packaging are traditional uses for flexographic printing, but it can be used for books, newspapers, or inserts. Inkjet presses are making incursions into the flexographic market as well.

LED UV:

LED UV is a curing technology. It uses light-emitting diodes (LED) that emit UV light to dry inks instantly as they pass through a press. The advantages are shorter waiting times for ink to dry so printed pieces can make their way to finishing and binding more quickly. It’s also quite eco-friendly as the lamps don’t contain mercury, which needs to be disposed of properly, and they don’t produce ozone gas. LEDs have minimal heat output, so we can use them for a broad array of print applications on heat-sensitive substrates, such as thin slides and self-adhesive sheets. Because the ink has less time to settle into the substrate, colors are clear and sharp.

Because of its ability to dry ink instantly and produce bright, vivid colors, LED UV can turn an ordinary piece into a luxury, high-quality product.

Dye Sublimation:

Dye-sublimation is a printing process in which heat is used to transfer ink onto fabric.

A design is printed onto a special paper placed against the material. When heat is applied, the inks turn to gas and are transferred into the fabric at the molecular level. Sublimation refers to turning a solid into gas. The results are nearly permanent, and will not crack, fade, or peel under normal conditions. Dye sub printers produce continuous tone images as opposed to halftones, which are used in offset litho. Inkjet is also making inroads into this market.

We use dye-sub printers largely for printing on polyester or other synthetic textiles, such as flags, banners, photos, novelty items such as cell phone covers, and other items that have sublimation-friendly surfaces.

Many printing projects can technically be executed on multiple presses. The decision of which technology to use comes down to production efficiencies, running costs of the press and, consequently, prices, run lengths, objectives, and optimum quality desired. Your printer can give advice on the best process for your project. Get them involved as soon as possible in the creative process to achieve the best outcome.

Join the Color Collective

Registration is FREE and only takes a moment

- Latest industry advice

- News, Article, Technology

- Events & Awards,

- And lots more...

all focused on designing for production print, textile, packaging